Call: 08071630589

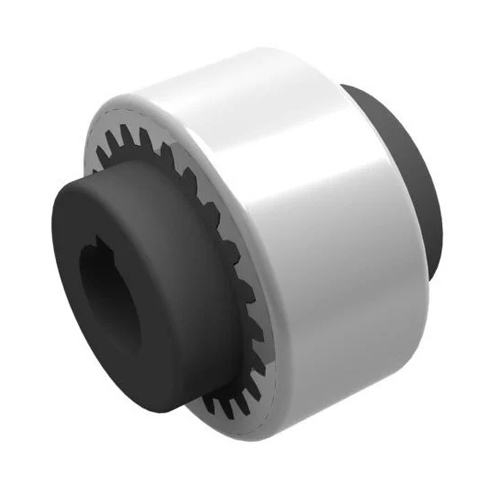

Nylon Gear Coupling

Price 350 INR/ Piece

MOQ : 1 Piece

Nylon Gear Coupling Specification

- Head Code

- Round

- Material

- Metal

- Usage

- Industrial & Commercial

- Standard

- High

- Product Type

- Gear Coupling

- Color

- Black-White

- Shape

- Round

Nylon Gear Coupling Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 1500 Pieces Per Month

- Delivery Time

- Days

- Main Domestic Market

- All India

About Nylon Gear Coupling

Gear Coupling is a type of mechanical device that is utilized for connecting two shafts in a rotating system. It is featured with two hubs with outer teeth that mesh together that transmits torque between the shafts. The teeth are designed for allowing for some degree of misalignment between the shafts while keeping a continuous speed ratio. It is generally utilized in a lot of heavy-duty industrial applications where high precision and torque are required, such as in construction, mining, and steel industries. The Gear Coupling is known for their reliability, robustness, and ability to accommodate axial, angular, and radial misalignment.

Precision Engineered for Diverse Industries

Designed to meet the rigorous demands of industrial and commercial settings, our nylon gear couplings provide seamless power transmission. Their robust construction ensures minimal maintenance and extended service life, making them suitable for machinery where reliability is critical.

Trusted Network Across India

As a reputed distributor, manufacturer, supplier, trader, and wholesaler, we cater to clients all across India. Our efficient supply chain enables us to deliver high-standard nylon gear couplings swiftly, ensuring that your operations remain uninterrupted.

FAQs of Nylon Gear Coupling:

Q: How is the nylon gear coupling installed in industrial machinery?

A: The nylon gear coupling is typically installed by aligning the shafts of two pieces of machinery and securing the coupling onto the shafts using set screws or clamps. It allows for slight misalignments and provides smooth torque transmission.Q: What makes the nylon gear coupling suitable for both industrial and commercial use?

A: Its robust metal construction, high-standard manufacturing, and reliable design make it ideal for heavy-duty industrial applications as well as moderate commercial setups. The coupling delivers durability, flexibility, and consistent performance under varying loads.Q: When should I consider replacing my existing gear coupling with this product?

A: You should replace your existing coupling when you notice increased vibration, noise, or visible wear and tear. Upgrading to our high-standard nylon gear coupling ensures better operational efficiency and minimizes unscheduled downtime.Q: Where can I purchase this nylon gear coupling in India?

A: You can purchase our nylon gear coupling through our network of distributors, suppliers, traders, and wholesalers across India. Contact us directly for assistance in finding a local provider or to place a bulk order.Q: What is the manufacturing process for the nylon gear coupling?

A: Our coupling is manufactured using precision engineering with high-grade metal and premium nylon components. The process includes rigorous quality checks to meet high industrial standards and to guarantee performance and safety.Q: How can the nylon gear coupling be used in various applications?

A: It is versatile and can be used to connect shafts in pumps, conveyors, compressors, and other machinery requiring reliable power transmission. Its round shape and robust material make it suitable for a wide range of setups.Q: What are the main benefits of using this nylon gear coupling?

A: Key benefits include superior wear resistance, minimal maintenance requirements, ease of installation, and the ability to accommodate minor shaft misalignments. Its high-standard metal construction assures long service life and operational safety.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Industrial Coupling Category

Love Joy Spider Coupling

Price 100 INR / Piece

Minimum Order Quantity : 1 Piece

Head Code : Round

Material : Metal

Shape : Round

Standard : High

Love Joy Coupling

Price 100 INR / Piece

Minimum Order Quantity : 1 Piece

Head Code : Round

Material : Metal

Shape : Round

Standard : High

Aluminium Love Joy Coupling

Price 100 INR / Piece

Minimum Order Quantity : 1 Piece

Head Code : Round

Material : Aluminum

Shape : Round

Standard : High

Encoder Coupling

Price 100 INR / Piece

Minimum Order Quantity : 1 Piece

Head Code : Round

Material : Aluminum

Shape : Round

Standard : High

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry